What organic fertilizer processing equipment is needed to make cow manure organic fertilizer?

First, the moisture of cow dung should be controlled below 85%. Then the straw powder can be added. The water content is controlled at 52%~68%. After the raw materials, auxiliary materials and bacterial agents are mixed and stirred, they can be piled for fermentation. The compost turner turns the pile evenly and thoroughly, turning the low-layer special materials into the middle and upper part of the pile to fully decompose. You should turn the pile once a day. When the temperature exceeds 70 degrees, you should turn the pile immediately, otherwise the beneficial microorganisms and fermenting bacteria will be killed in large quantities, which is not conducive to the fermentation.

The color of the fermentation materials will change to brown or dark brown, and the ammonium nitrogen content will increase significantly.The volume of the decomposed compost collapses by 1/3 to 1/2 compared to the newly pile. Then you can spread the fermented organic fertilizer evenly on the drying field. And the thickness should not exceed 20 cm. You should also turn it over to keep the moisture content below 32%.

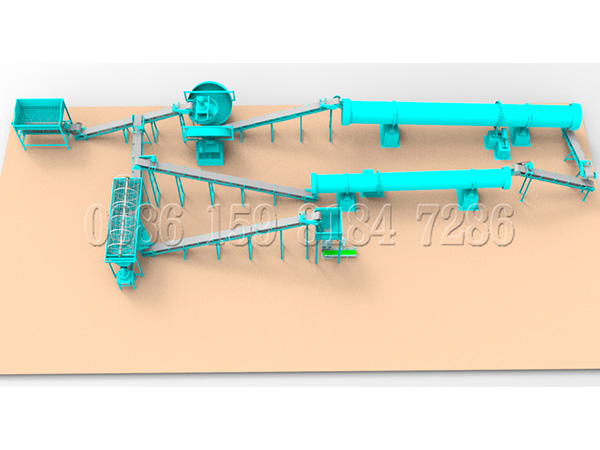

The whole set of granular organic fertilizer processing equipment equipped by Zhengzhou Shunxin Engineering Equipment includes fermentation equipment, pulverizer, mixer, granulator, dryer, cooler, screening machine, packaging machine, etc. There are many types of equipment for manufacturing fertilizers, and different organic fertilizer processing equipment plans need to be formulated according to the different materials and capacity. Welcome to contact us for specific information.