How to convert sheep manure into organic fertilizer through organic fertilizer production line

First, after the wet sheep dung is crushed, an appropriate amount of rice straw powder is added according to the water content of the sheep dung. Generally speaking, the amount of water required for fermentation is that when you grasp the raw materials, you can see the water, but they won’t droop. Then you can add corn flour and bacteria. The function of corn meal is to increase the sugar used for bacterial fermentation, so that the multi-dimensional complex enzyme bacteria quickly dominates.

Then the prepared mixture can be added into a mixer for a certain period of time to make the mixture evenly mixed without leaving any raw materials. The finished mixing raw materials can be piled into a pile with a width of 1.5m-2m and a height of 0.8m-1m. The temperature is raised in 2 days and there will be no peculiar smell in 4 days. It will become loose in 7 days and the change is in 9 days. The compost fertilizer can be finished in 10 days.

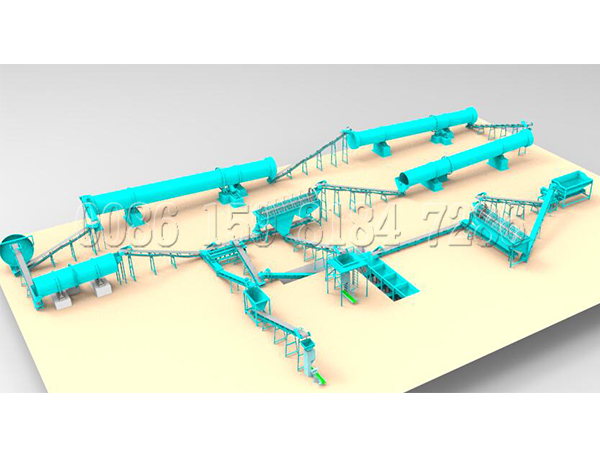

After a little drying, it can be crushed by a semi-wet material grinder and granulated by an organic fertilizer granulator. After the process of drying, cooling and screening, the final granules can be packaged to sale.