Client: Gemini Steel – www.gemini-steel.co.za

Country: South Africa

Industry: Transportation & Industrial Services

Contact Person: Mr. Louis Visser

Project: Rotary Dryer for Wood Chip Drying

Gemini Steel is a South African company engaged in the transportation and industrial sectors. As part of a strategic move into biomass processing and renewable energy support, the company required a reliable drying solution for large volumes of wood chips. Their aim was to optimize moisture control for downstream use in fuel production or industrial heating.

Efficient drying of wood chips with high initial moisture content

Stable and continuous operation

Low maintenance and energy-efficient system

Equipment suitable for outdoor or semi-industrial installation

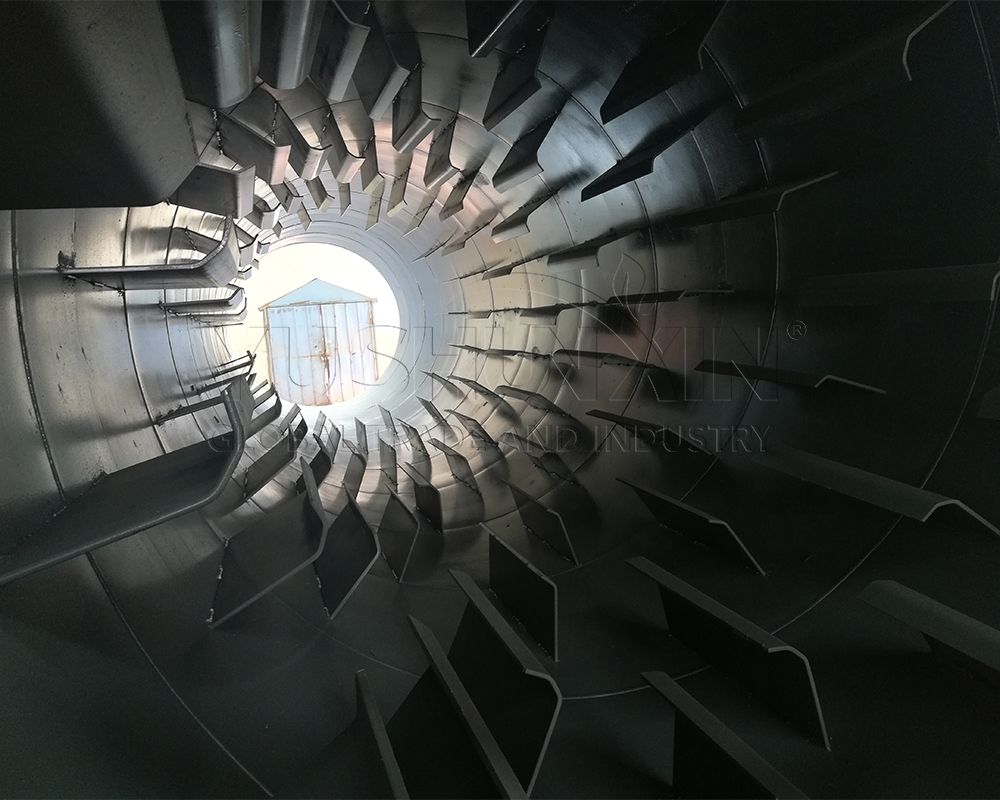

To meet the client’s demands, we supplied a high-performance rotary drum dryer designed specifically for wood chip drying. Key components included:

Feeding system with moisture adjustment capability

Large-diameter rotary drum with optimized lifting plates

Hot air furnace for consistent heat supply

Dust collection system to reduce emissions

Intelligent control system for temperature and speed regulation

Significant reduction in wood chip moisture content, improving combustion value

Smooth and stable operation even in high-volume processing

Enhanced energy efficiency, reducing operational costs

Low maintenance design, suitable for remote or industrial environments

Positive feedback from Mr. Louis Visser regarding system performance and after-sales service

The successful installation of the rotary dryer allowed Gemini Steel to take a key step in biomass material processing. By incorporating advanced drying technology into their operations, the company is now better positioned to support sustainable fuel production and maximize the value of wood waste resources in South Africa.